Maximizing Efficiency: Innovative Solutions for Paper, Wood, and Biomass Processing

The world uses huge amounts of paper and wood products, and it can be found in everything from books, newspapers, cardboard boxes, building lumber, and furniture. Paper and wood need to be processed and dried according to specific requirements for the end use, and any additives added accordingly.

Why use biomass dryers? Biomass is an up-and-coming alternative energy source that uses scrap wood and other waste products to dry them into compact pellets that burn clean and efficiently. Ensuring these biomass pellets are dried thoroughly without breakage or dust is important to burn them efficiently.

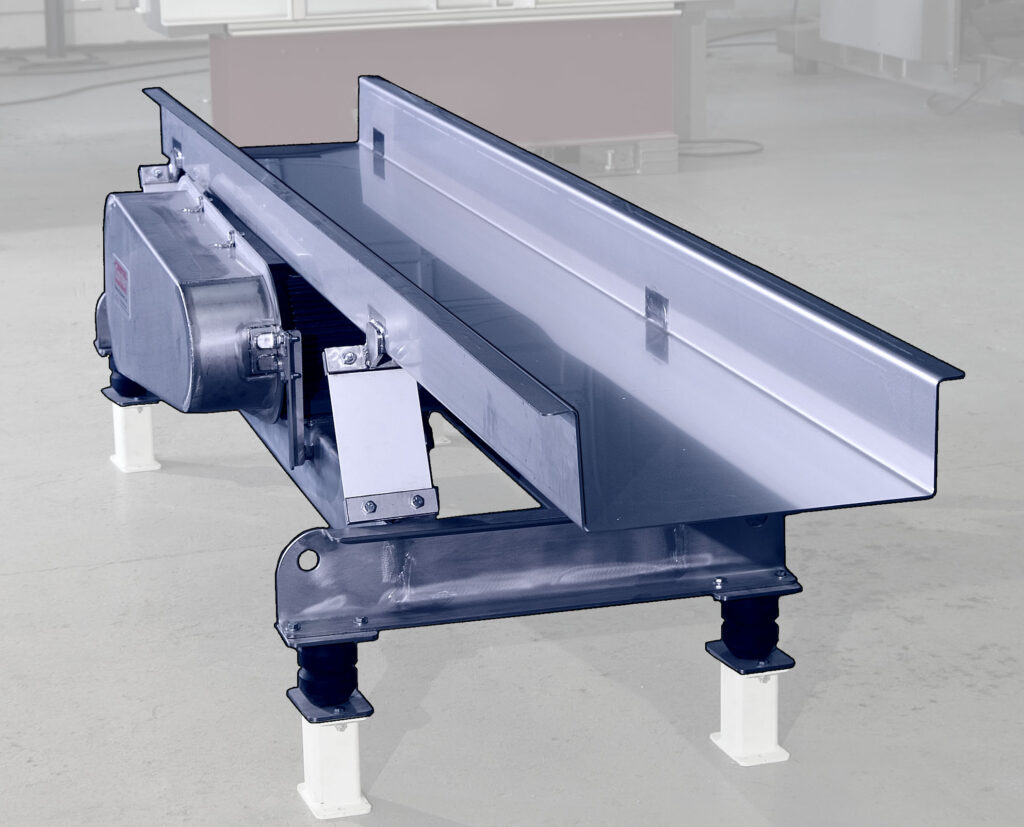

Vibrating Conveyors

Light-duty and medium-duty vibrating conveyors are ideal for transporting paper, wood, and biomass products without breakage or worrying about pieces being stuck underneath a moving conveyor belt. They don’t suffer from upset conditions in the case of large loads, and additional processing, dewatering, and drying can be performed along the conveyor.

Feeders

Feeders are made for handling paper and wood products and are designed to be able to withstand heavy loads from offloading and dumping. They can include a scalping or screening portion to keep unsuitable material from entering downstream.

Screeners

Screeners can be designed with up to five different decks with individually designed screens for custom separation needs on a single machine. They can help remove dust and debris and size particles based on need.

Vibrating Fluid Bed Dryers & Coolers

Vibrating fluid bed dryers and coolers can thoroughly and evenly dry paper and wood products to the required moisture levels without material degradation. The use of heated air blown from underneath and angled vibrations creates a moving fluidized bed of material, drying every surface of the product evenly, unlike with other radiant styles of heaters. A cooling zone allows the product to continue to dry through evaporative cooling while increasing equipment efficiency and reducing fuel costs.

Spiral Elevators

Spiral elevators are ideal when material needs to be elevated within a small footprint and can be outfitted to perform additional processing, drying, or cooling while conveyed.