Posted on November 1st, 2022 by Carrier Vibrating

Carrier Vibrating Equipment Inc. was recently approached by a major U.S.-based producer of fine salt to help resolve a problem they had been experiencing. The salt production approach at this facility uses gas-fired evaporators to generate a salt-wet cake from a brine solution. After the evaporators, the wet cake is dried using rotary filter drums with hot process air passing through the wet cake on the filters. This process resulted in a fine-grain salt exiting the rotary drum filter dryer at a temperature of approximately 260°F.

The Problem

At this facility, the salt is primarily used for two purposes: the production of water softener pellets and the production of table salt. In the production of water softener pellets, the high temperature of the salt was beneficial to forming pellets. However, for the production of table salt, the high temperature caused problems with packaging the final product. The existing method used to cool the salt utilized large storage bins to hold it while it cooled before packaging. The method, however, required significant manpower and floor space in the production facility and resulted in damage to the package labels due to inadequate cooling, adding significantly to the production cost.

The Solution: Vibrating Fluid Bed Coolers

The client was considering traditional cooling technologies such as rotary coolers and fluid bed coolers and even contacted Carrier to inquire about vibrating fluid bed coolers since the company had recently purchased a vibrating fluid bed drying system for salt from Carrier. In discussions with the client, it was determined that the existing floor space available for cooling was severely limited and that the use of coolers utilizing process air to cool the salt – such as rotary coolers or fluid bed coolers – would have made the limited space available an even bigger impediment to using this type of cooling. These types of coolers would also require the use of a process cooling air fan, a dust collector for the exhaust, an exhaust fan, and interconnecting ductwork. All of this ancillary equipment, the air requirements, and a large installation cost would have also made these technologies cost-prohibitive.

VibroCool Solution

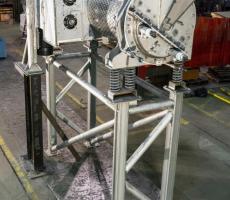

Carrier instead offered a solution based on new technology that had been recently developed. The new technology was based partially on existing technology used in the foundry industry combined with Carrier’s extensive knowledge of indirect heat transfer via immersed heat exchangers. The unit offered was Carrier’s VibroCool cooler. The VibroCool cooler is a cylindrical horizontal drum with a horizontal tubular heat exchanger bundle mounted internally, through which cooling tower water or filtered river water is circulated as a heat transfer media. The drum assembly is supported to its foundation via steel coil isolation springs, and the unit is vibrated using a gearbox-driven eccentric weight drive to produce a unique vibratory motion. The vibratory motion causes the salt to move slowly through the machine in a gentle, well-mixed, sub-fluidized state. The heat exchanger is mounted in the unit such that the circulating bed of well-mixed salt is in intimate contact with the heat exchanger, resulting in high heat transfer with the cooling water.

A continuous test unit was shipped to the plant site to demonstrate the VibroCool’s ability to process the table salt. The unit was trialed by pulling a slipstream of material directly from the target process line. Carrier’s engineers worked with the plant personnel to determine the product quality and efficiency of the unit. The testing proved that by utilizing in-bed heat exchangers and the specific vibratory motion, the VibroCool achieved an excellent heat transfer coefficient with no degradation to product quality.

A production unit was then designed to handle the plant’s full line capacity, cooling from 260°F to less than 140°F. The size of the unit required was determined to be 3 ft in diameter and 12 ft in length. The unit was constructed of 316L stainless steel with all product contact surfaces polished to a food-grade finish. To make the installation process easier, all of the water supply and return lines were close-coupled with a single connection in and out. The only other required connection was a single-point electrical connection for the drive motor. The unit was built with a support structure for this particular plant but is inherently a low-headroom design. This unit could be placed in a building with ceiling heights as low as eight feet. For this application, the VibroCool utilizes simple screw conveyors for feed and takeaway conveying, making the entire process both simple and flexible.

The production of VibroCool achieved the client’s desired cooling capacity with a compact, highly efficient, economical, and easy-to-install design. These benefits, combined with expected years of trouble-free service and the added benefit of eliminating regulatory permitting, made the client’s decision to purchase the VibroCool easy.

Download the VibroCool – Powder Bulk Solids article