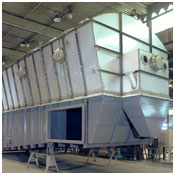

Fluid Bed Drying & Cooling Systems

Fluid bed processing has a number of applications. The most common in process industries are drying and cooling, agglomeration and air classification. Carrier offers a variety of fluid bed dryer/cooler systems which have proven reliable in applications around the world, and with dryer designs that can be customized to meet your needs.

Carrier Fluid Bed Dryer Types

- Vibrating Fluid Bed Dryers – cool and dry a wide range of material types at a variety of feed rates. Ideal for materials with wide particle size distribution.

- Conventional Fluid Bed Dryers – provide efficient processing including drying, cooling, classifying and sterilizing.

- Media Slurry Dryers – are cost-effective in the production of super fine powders from liquid phase reaction or wet grinding operations. High viscosity materials can be pumped directly into a slurry dryer without mixing or atomization.

- Flash Dryers – inexpensive solutions to drying powders and granular materials. A flash dryer can use higher gas temperatures than most other type dryers because the material retention time is very short. Flash dryers are capable of processing high capacities in a relatively small amount of space, and are often used as a pre-dryer to expand production capacity on existing lines.

- Tornesh Dryers – combine many of the benefits of fluid bed and flash drying. The unit can process wet solids ranging in size from 1 micron up to one-half inch diameter. Materials to be dried fall to the bottom plenum of the tornesh dryer and begin to swirl in a cyclonic pattern. As moisture is removed from the product, it becomes lighter and eventually is entrained in the upward hot gas stream.

Basic Theory of Fluid Bed Dryers, Slurry Dryers, Flash Dryers & Tornesh Dryers

To understand fluid bed dryer systems, it is important to be familiar with fluid bed operation. Fluid bed processing passes a gas directly through a bed of solid material via a perforated plate, nozzles, ceramic grid or other fluidizing media, lifting and mixing the solids. As the velocity of the air increases, so does the pressure drop across the bed until at a certain flow rate, the frictional drag on the particles equals the material bed’s effective weight. At this fluidizing velocity, the material bed attains fluid-like properties and expands beyond the size of the fluid bed. When the air velocity in the free cross-section is further increased, the bed expands until particles are carried over by the air. By fluidizing the bed, each particle is enveloped in the process gas creating an extremely efficient heat transfer device.

More on our vibrating fluid bed dryers, conventional fluid bed dryers, slurry dryers, flash dryers and Tornesh dryers.